What are the key features to consider when selecting a stainless steel quick coupler?

When selecting a stainless steel quick coupler, there are several key features to consider. These features will depend on your specific application requirements. Here are some important factors to consider:

1.Material: Stainless steel quick couplers are known for their durability and resistance to corrosion. Ensure that the coupler is made of high-quality stainless steel that is suitable for your intended use.

2.Pressure and temperature ratings: Check the maximum pressure and temperature ratings of the coupler to ensure it can handle the operating conditions of your application. It is crucial to select a coupler that can withstand the specific pressure and temperature ranges you will encounter.

Choose a coupler with a high-pressure rating, such as 5000 PSI (pounds per square inch), and a wide temperature range, such as -40°C to 200°C, to handle demanding operating conditions.

3.Connection type: Consider the connection type required for your application. Quick couplers come in various connection types, such as threaded, push-to-connect, camlock, or bayonet-style connections. Choose a coupler that matches your existing equipment or system.

Select a threaded stainless steel quick coupler if you need to connect it to threaded pipes or fittings. Alternatively, opt for a camlock coupler for quick and easy connections without the need for threaded engagement.

4.Size and compatibility: Determine the appropriate size of the coupler that matches your system's piping or hose diameter. Ensure compatibility with other components or fittings to ensure a secure and leak-free connection.

Consider a 1/2-inch stainless steel quick coupler if your system's piping or hose diameter is 1/2 inch. Ensure compatibility with other components, such as matching thread sizes or hose diameters.

5.Flow rate: Consider the required flow rate for your application. Different couplers have varying flow rates, so select one that can accommodate the desired flow without causing restrictions or pressure drops.

Choose a stainless steel quick coupler with a high flow rate, such as 50 gallons per minute (GPM), if you require rapid fluid transfer or high-volume applications.

6.Safety features: Look for safety features such as locking mechanisms, safety latches, or double-valve systems that prevent accidental disconnection and ensure a secure connection during operation.

Look for stainless steel quick couplers with locking mechanisms that prevent accidental disconnection, ensuring a secure connection during operation. For example, couplers with a spring-loaded locking sleeve provide an added layer of safety.

7.Ease of use: Evaluate the ease of connecting and disconnecting the coupler. Quick and simple connection mechanisms can enhance efficiency and reduce downtime during equipment setup or maintenance.

Consider a push-to-connect stainless steel quick coupler that allows for quick and effortless connections without the need for additional tools or threading.

8.Seal type: Consider the type of seal used in the coupler. Common options include O-rings or gaskets. Ensure the seal material is compatible with the fluids or gases used in your application to prevent leaks or contamination.

Look for stainless steel couplers with high-quality O-rings or gaskets made of materials such as Viton or EPDM, ensuring compatibility with various fluids and offering reliable sealing properties.

9.Chemical compatibility: Verify the compatibility of the coupler's stainless steel material with the specific chemicals or substances it will come into contact with during operation. Some chemicals or environments may require specific grades of stainless steel for optimal performance and longevity.

If your application involves corrosive chemicals, choose a stainless steel quick coupler with specific chemical resistance properties, such as Hastelloy C276 or Monel, to ensure compatibility with the specific substances used.

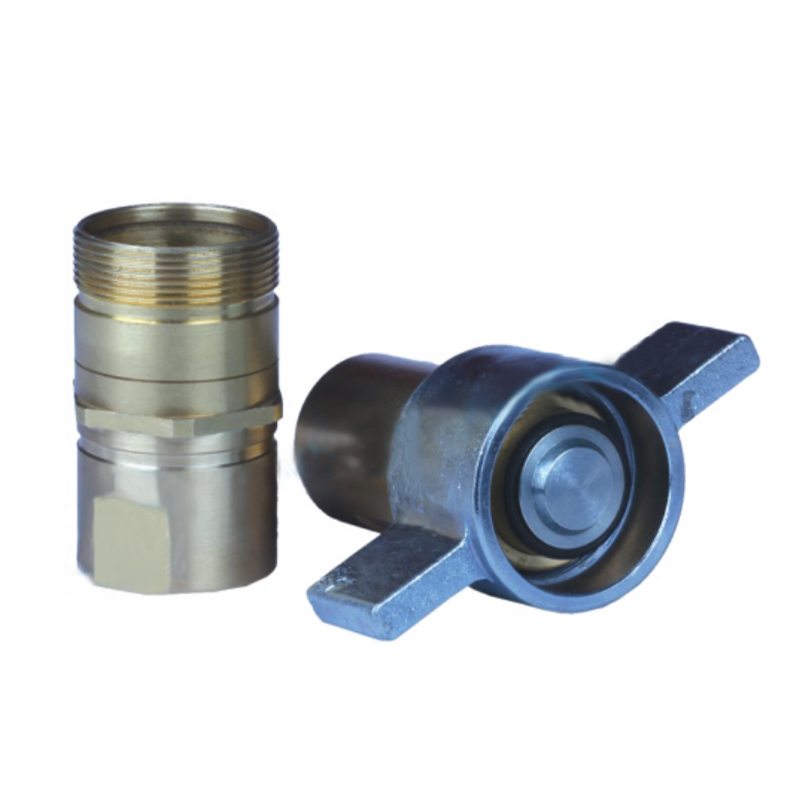

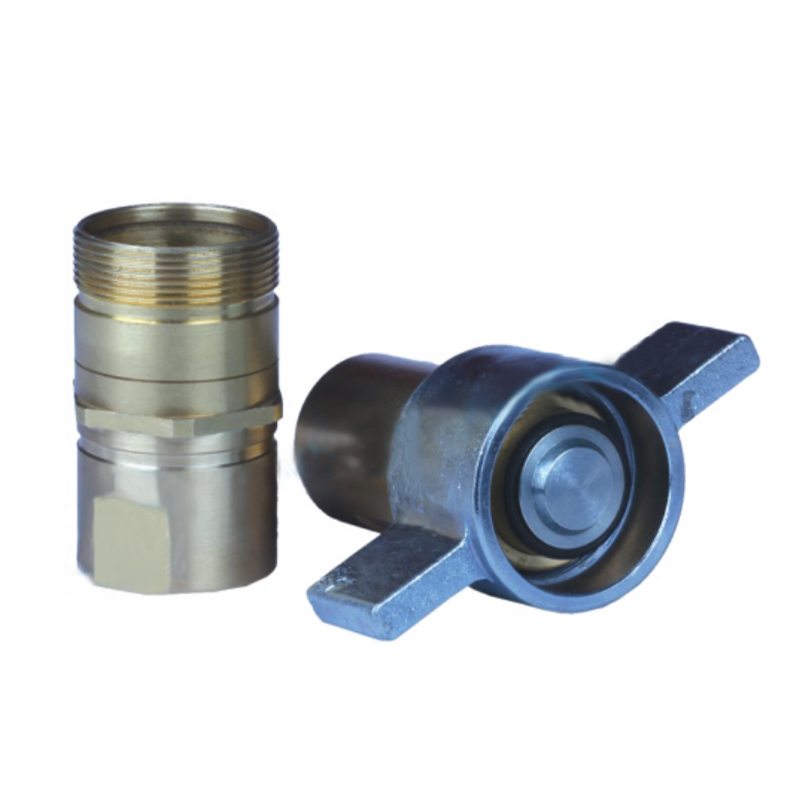

GT-L2 Heavy-dust wing nut thread type hydraulic quick coupling

The GT-L2 Heavy-Dust Wing Nut Thread Type Hydraulic Quick Coupling is a type of hydraulic coupling used to connect and disconnect fluid lines quickly and easily. This type of coupling is commonly used in hydraulic systems in industrial applications, such as manufacturing, construction, and agriculture.

The GT-L2 coupling is designed with a wing nut thread type, which provides a secure connection and is easy to use. The heavy-duty construction of the coupling makes it suitable for use in harsh environments, where dust and debris can be a problem.

This type of coupling is designed to prevent fluid loss and minimize air inclusion during connection and disconnection. It features a poppet valve design that allows for a high flow rate and minimal pressure drop.

Contact Us